Specifications

Basic Unit

- Touchscreen control panel

- Integrated tube reservoir for 500 tubes

- Automatic correct alignment of tubes in carrier

| Category | FeednSorter |

| connections |

USB |

| Dimensions |

Length: 600mm width: 300mm Depth: 40mm |

| weight | 12 kg |

| power | 230 V |

Feeder and Sorter

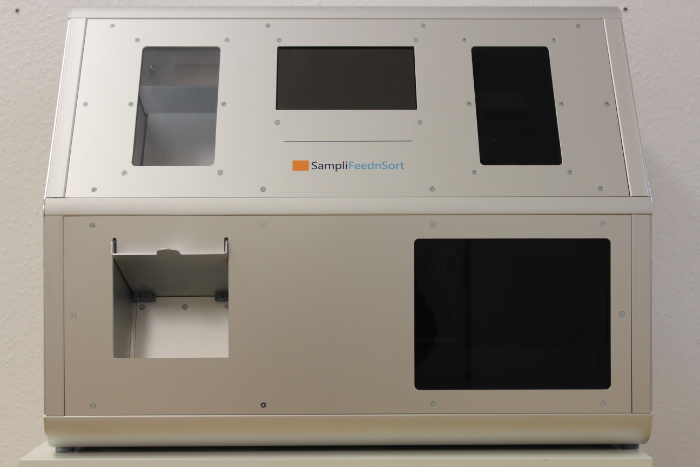

SampliFeednSort

Absolute flexibility when labeling.

From now on you only order loose tubes in bags because the sorting of Tube to Carrier has never been so time efficient and easy. Save valuable resources by reusing your empty carrier, save manpower and you are taking time management to a new level.

Within 2 minutes the FeednSort automatically fills a carrier in SBS format with 48 tubes and the equivalent of 96 tubes in less than 5 minutes.

We are flexible when it comes to the choice of tubes.

The SampliFeednSort comes with either a 4 position SBS worktable or alternatively delivered with a worktable for 2 of 9 x 9 or 10 x 10 boxes.

For integration, the worktable can be equipped with just one SBS position and an extended stage. Thus, you can use your liquid handling platform or usefully supplement other automation systems

With the two-in-one device SampliFeednSort will solve two problems. Feeding as well as sorting are covered by the device.

The device has a very small footprint and fits on any laboratory workbench.

The low weight and small footprint also allow the SampliFeednSort to be used at different locations in the lab.

Module specifications

Step conveyor in perfection

The newly developed step conveyor allows high transport speed with consistently precise alignment of the tubes. Two connected conveyor belts ensure further transport. The feeder holds approx. 800 – 1000 tubes, depending on the size of the tubes.

Display with touchscreen

The new freedom when sorting: Click on individual layouts/patterns or save up to 10 recurring processes as fixed programs. If you want to deviate from the pattern, this can easily be changed using the touchscreen.

It is only saved if you press save.

Just-in-time camera surveillance

An integrated camera system ensures optimal process monitoring. Intelligent image processing recognizes the desired tube. Defective tubes are sorted out.

The device is trained for all the tubes present. Errors that have already occurred are taken into account with the error correction program.

SAMPLISFeednsort – pICS

SampliFeednSort- VIDEO

Optionscan be retrofitted at any time

- model to integrate with

extended stage - Camera system

Order-Information

SampliFeednSort 5001

base unit with 2 SBS positions