Specs

Base Units

- 10 position worktable for SBS format racks or custom format

- Control completely integrated into the device

- Operation via external PC, web-based software

- Vacuum gripper, automatic tube and height detection, tubes from 20-130 mm possible

- integrated thermal transfer printer, 600 dpi

- Width843 mm

- Height: 1400 mm

- depth: 680 mm

- 95 kg

- Compressed air: 6 bar constant flow must be guaranteed

- 2 USB-connections for Handheld Barcode Scanner, Memory Stick, RJ45 network connection

- 230 Volt

Process Solution

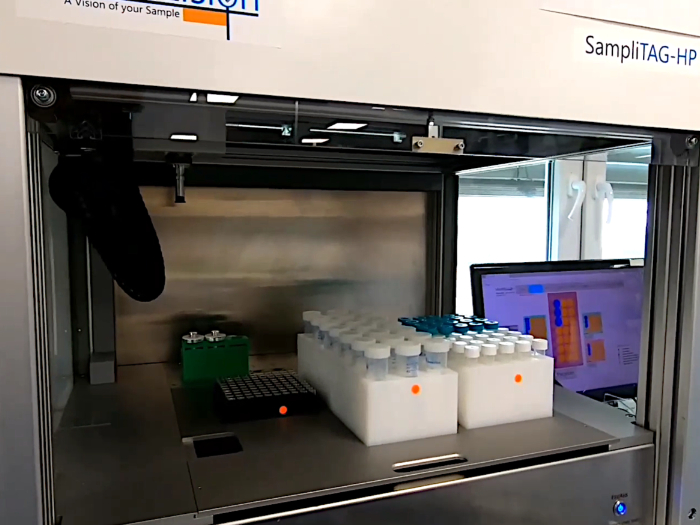

SampliTAG HP Plus – High Performance Tube Labeler

+ Liquid Handling

Safe sample preparation of quality control samples – Labelling, verifying, filling, capping, and recapping, weighing. Design individually according to your requirements

In quality control analysis, many samples are checked daily for various parameters. There are also time-critical parameters that must be analyzed. Depending on the size and type of company, these samples may also occur in shifts.

In many companies, the data for sample analysis comes from a LIMS system. The sample containers are often still labeled and filled manually. We developed the SampLiQua to standardize this process and automate time-consuming routine work.

Aliquots from larger containers or even smaller tubes that come from production can be aliquoted to a wide variety of tubes. Regardless of whether the samples are intended as reserve samples or samples are to be used directly for analysis, the SampLiQua can be used in a variety of ways. An on-board capper/recapper opens or closes tubes and a liquid handling unit, which can be selected depending on the requirements, pipettes the sample from the source tube and aliquots it into the desired tube. The tube, which has already been labeled, is now transferred to a carrier and can be promptly removed for further processes. The data for printing and possibly for the complete method come from a LIMS system. Detailed log files and the generation of audit trails ensure high process reliability and traceability.

This automation of sample preparation not only automates time-consuming processes, but also standardizes them. Incorrect assignments are greatly reduced. The unique identification of the sample by barcode and/or plain text is ensured. The tracking of the sample is already ensured at the beginning of the sample preparation. Paperless tracking is now becoming a reality.

The system can be supplemented with various modules such as liquid handling, capper and recapper, as well as weighing systems. Barcode scanners can either verify or identify. The SampLiQua represents an excellent alternative to expensive fully automated solutions for flexible small-scale production.

Other key features include sophisticated data management and retrieval. Secure internet-based software also enables remote control from a remote location.

The advanced data management system is based on SQL Server. 21 CFR Part 11 is possible on request.

Features

- Tubes from 20mm to 130mm in height and from 8 – 35mm in diameter

Label, fill, open, close, and much more tube heights in one run on the same worktable. Application ranges from 20 – 130mm, whether internal or external thread tubes - Automatically height-adjustable labelling station

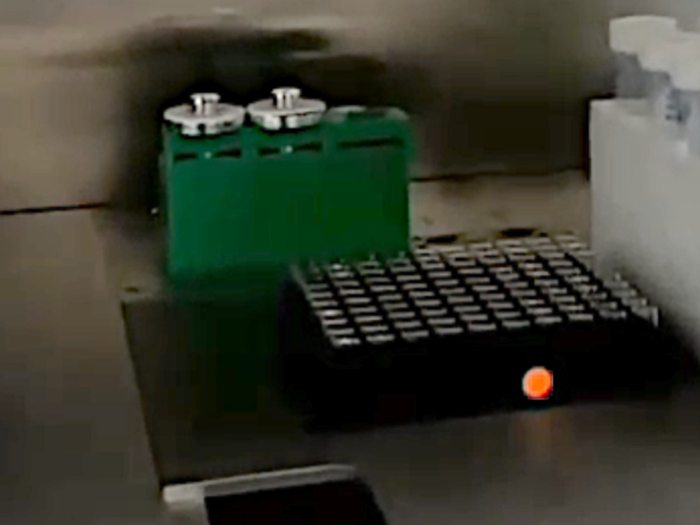

No change required for other tube sizes; position programmable - Worktable with 10 SBS positions or special table for QuEChERS or other methods

10 SBS position worktable or custom formats possible - Worktable easily interchangeable

Different worktables can be used – Automatic Worktable verification - Interchangeable Vacuum Grippers – Parking space for vacuum grippers

Automatic on-board exchange of vacuum grippers - Control Software

Can be connected from different PC’s, web-based software

User Management - Throughput per hour

300 – 500 tubes per hour depending on application - Barcode Scanner

Bottom- and or Side Barcode Scanner for all 1 D and 2 D Codes - Liquid Handling

Peristaltic pump or positive displacement pipetting module - Capping / Recapping

Capper / Recapper module to open and close tubes

MODULE

Liquid Handling

Positive Displacement Pipette

- excellent petting accuracy and precision

- ideal for dispensing small volumes

- no cross-contamination and carry-over

- flexible: various tip sizes available

- automation tip ejection

- integrated liquid level detection

- tip presence sensor

- conductive tips necessary

Peristaltic pump

The smallest flip-top peristaltic pump is available. With an elegant body design of just 40 x 62 mm (width x height) it stands just 21.5mm (depth) off a panel mount. The flip-top design allows tube loading and unloading with ultimate ease.

- Flow rates from 10μl to 200 ml/min

- Flip-top design for continuous tube

- Floating saddle for tube life > 2000 hours

- Repeatability to 1% over tube life

- 5 different tube sizes

- 3, 4 or 6 roller configurations

Capper / Decapper

- Capper / Decapper Modul

Adjusted to the respective torque of the tube

Barcode scanner

- Bottom and/or side barcode scanner

3, 4 or 6 roller configurations

reading distance: 40 – 75mm

camera resolution: 1280 x 960px

Degree of protection: IP67

SampLiTAG HP Plus – Pics

SampliTAG HP Plus Capper Init – Video

SampliTAG HP Plus Get DiTi – Video

SampLiTAG HP Plus Liquid detection – Video

Available Module

- Barcode Scanner, Bottom and or Side Scanner

- Color sensor, detection of different colored caps or tubes

- Direct printing process with inkjet printer

- Peristaltic pump or positive displacement pipetting module

- Capper / Recapper

- Weighing

Order Information

SampliTAG HP Plus 2001

Automatic tube labeler, Base unit with 10 SBS position Worktable

SampliTAG HP Plus 2001-WT-001

Worktable with built-in detection

SampliTAG HP Plus 2001-100

Side and or bottom Barcode Reader

SampliTAG HP Plus 2001-LM

Automatic height adjustment for labelling station

SampliTAG HP Plus 3001-LD-03

Liquid handling module – positive displacement

SampliTAG HP Plus 3001-DC-01

Decapper with screw cap holder for cryo tubes

SampliTAG HP Plus 3001-DC-02

Decapper with screw cap holder for Falcon tubes