Specifications

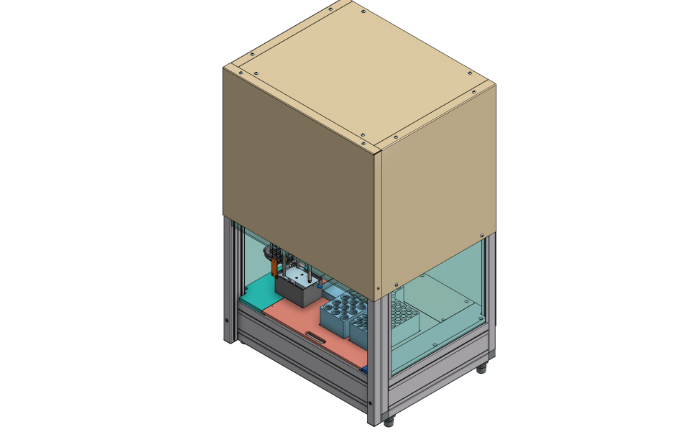

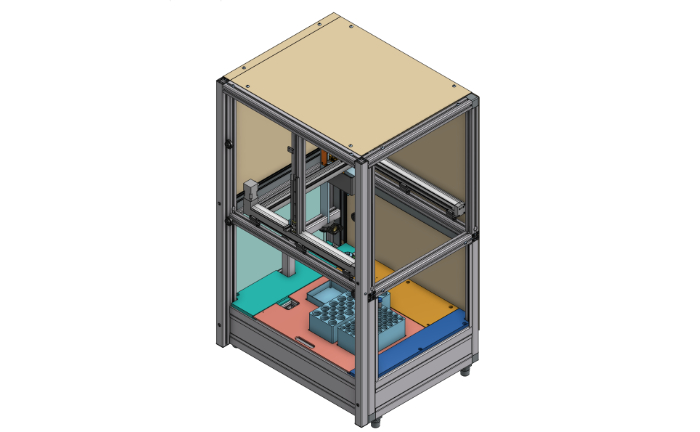

Basic Unit

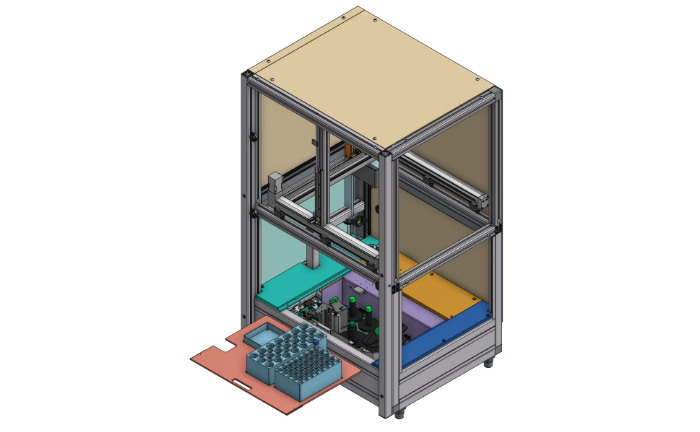

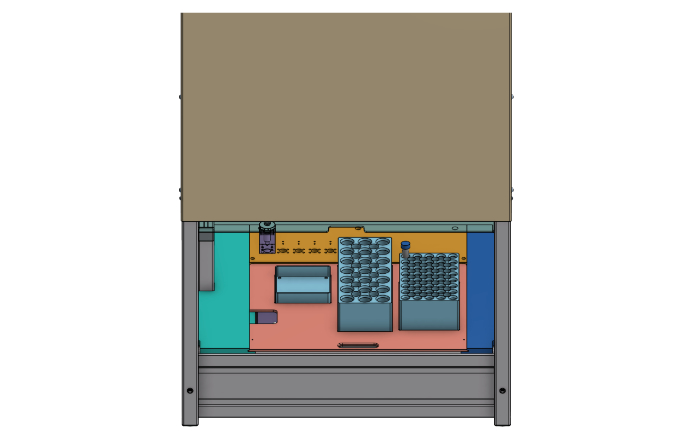

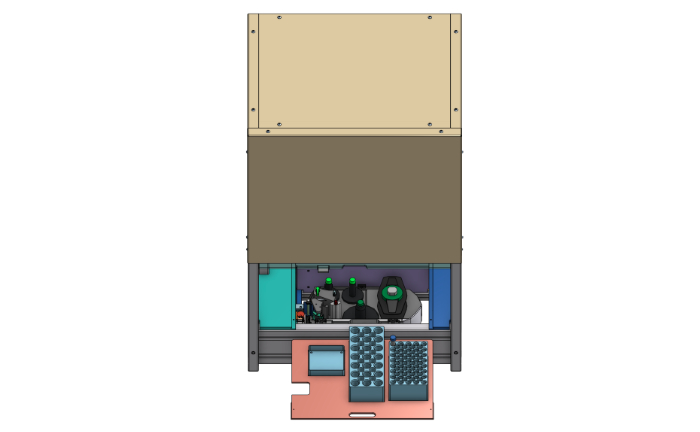

- 10 position worktable for SBS format racks or customized format

- Control completely integrated into the device

- Vacuum gripper, automatic tube and height detection, tubes from 20-130 mm possible

- Integrated thermal transfer printer, 600 dpi

| Category | Combination device |

| Operation | Operation via external PC |

| Compressed air | 6 bar |

| Connection |

2x USB RJ45-Network |

| Dimensions |

width: 843mm high: 1400mm Depth: 680mm |

| Weight | 65 kg |

| Power | 230 V |

Combination device

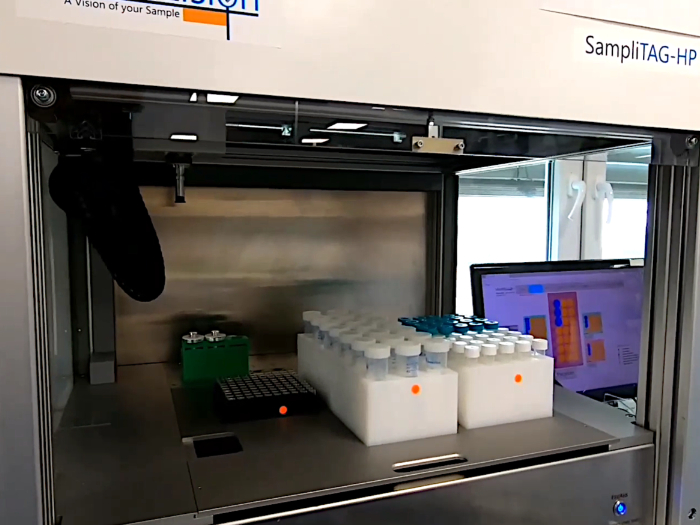

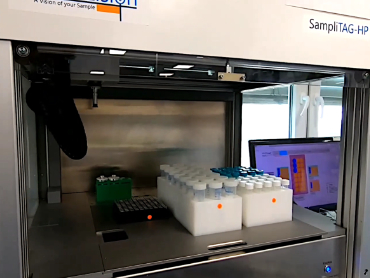

SampliTAG HP – High Performance Tube Labeler

Automatic Tube Labeling, Dispensing – Filling, Capping –

Recapping of various tube types in ONE RUN

The challenges of individuality and flexibility of a filling and labeling system have unfortunately not changed in many areas, despite standardization and automation. For example, sample containers come from production and retained samples must be filled and labelled for quality control and security reasons. Applications in analytics are standardized, but require a constant, different set of tubes. To meet these and similar requirements, we have expanded our SampliTAG line with a highperformance device SampliTAG HP. This can be supplemented with various liquid handling modules, cappers and recappers, as well as weighing systems.

The SampliTAG HP is an excellent alternative to expensive, fully automated solutions for flexible, small-scale production. The system meets the requirements of flexible small-scale production and at the same time delivers consistent production quality that is not possible with manual filling, sealing and labeling.

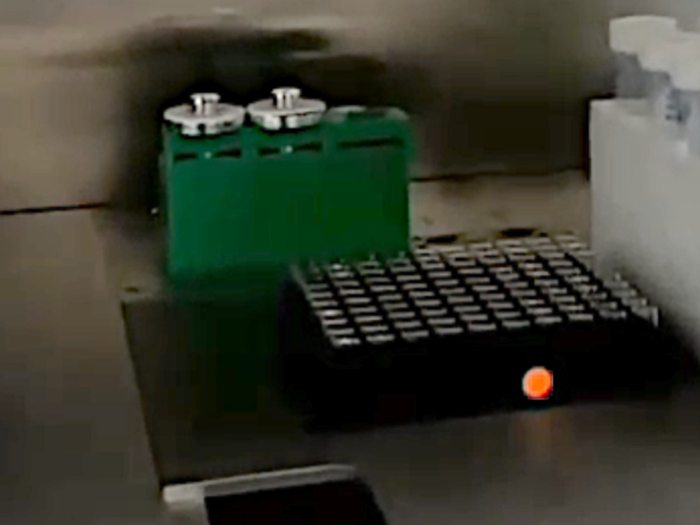

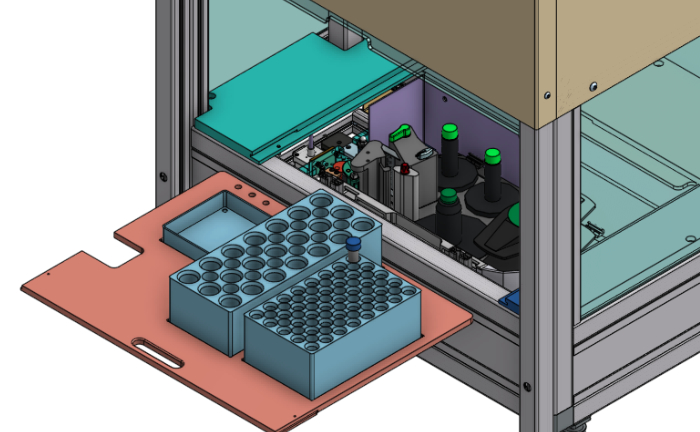

The modules include automatic tube feed, capping / recapping, verification, and scanning, labeling, tube feeding, liquid handling as required, and weighing. High-precision filling is possible either with pipette tips or a peristaltic pump.

Tubes with a height of 130mm and a diameter of 8mm – 35mm can be used as standard. Carriers for various tube formats are available or can be made accordingly. The complete system was developed for users looking for flexibility in production and laboratory routine.

Other main functions include sophisticated data management and retrieval. Secure internetbased software enables remote control from a remote location. The advanced data management system is based on SQL Server and is fully accessible from any web device. 21 CFR Part 11 is possible on request

Features

- Tubes from 20mm to 130mm in height

and from 8 to 35mm in diameter - Automatically height adjustable

label applicator station - Worktable with 10 SBS positions or

special table for the Quecher method - Worktable easily exchangeable

- Interchangeable vacuum grippers –

parking space for vacuum grippers - Control software web based

- Throughput per hour

- Bottom and / or side Barcode Scanner

- Liquid Handling

- Capping / Recapping

SampliTAG HP – Pics

Liquid Handling Module

Optimize your aliquoting of day-to-day quality control samples with our liquid handling modules. Easily place source tubes or vials on the SampliTAG HP. Our modules can handle pipette tips with a maximum tube size of 250 ml, while larger containers can be processed with a special liquid handling module.

The selection of the appropriate liquid handling module depends on the desired aliquoting volume and the source vessel. We can offer pipette tips, positive displacement or a pump module.

Let us know your requirements and we will recommend the right solution for you.

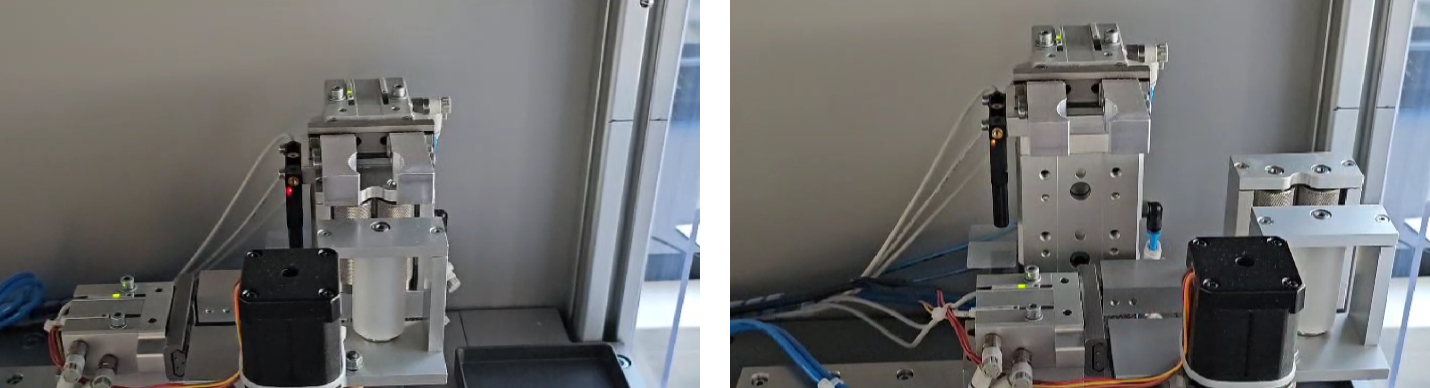

Capper/Decapper

Our capper/recapper is individually adapted to the tubes or vessels you use.

Before each aliquoting process, you have the option of first labeling the tube and then filling it. In this case, the cap of the tube is removed before filling, the tube is transported to the liquid handling station and closed again after filling. Labelling can be added before or after this process.

Alternatively, the capper can also be used exclusively for removing lids.

Weighing system

The weight control of liquids or solids in vessels is widely used in analytics.

Our weighing system offers the option of weighing vessels either before labeling as empty vessels or weighing the filled tube after the process. The vibration-free mounting of the balance ensures precise measurements.

Simply place a tube in the opening provided and have it weighed. The data is seamlessly transferred to a CSV export file

Barcode Scanner

A 2 D bottom barcode scanner can be used to retrieve data as well as to verify the barcode.

The barcode data can be used either as import or export file.

Can be used with all standard 2 D bottom barcodes from Matrix, Brooks, Micronic, Greiner, LVL and others. Barcoded labels are easy to verify with the side barcode scanner.

A process control that is very easy to implement.

Options can be retrofitted at any time

- Barcode scanner, bottom, and/ or side barcode scanner

- Color sensor, differentiation of different lid / tube colors

- Direct printing process with an inkjet printer

- Peristaltic pump, pipette tip or syringe pump

Ordering Information

SampliTAG-HP 3001

SampliTAG HP automatic tube labeler with 9 positions

(12 or 15 position worktable or special formats on request)