Allow samples in the laboratory

Our Intelligent labeling systems

Samplision offers automated labeling of laboratory vials.

We combine proven labeling technologies with innovative software, new technical implementation and high flexibility. We develop systems that meet the “Paperless Lab” goal. It goes without saying that we scan or verify samples.

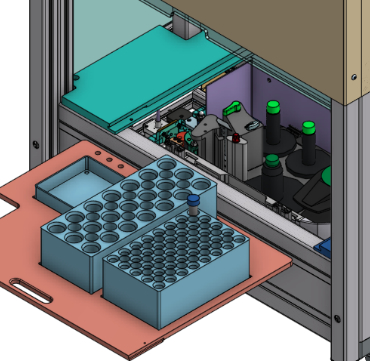

SampliTAG HP – High Performance Tube Labeler

The SampliTAG HP is an excellent alternative to expensive, fully automated solutions for flexible, small-scale production.

- Tubes from 20mm to 130mm in height and from 8 to 35mm in diameter

- Automatically height adjustable label applicator station

- Worktable mit 10 SBS Positionen oder Spezialtisch für Quecher Methode

- Interchangeable vacuum grippers – parking space for vacuum grippers

SampliONE

In many laboratories’ and the pharmaceutical industry, tubes, test tubes or other vessels are still used that do not conform to a standard. Tubes and vessels are often already filled with liquid.

- Single Tube Labelling Position

- control software integrated

- Operation via external PC

- Tube diameter from 8mm – 30mm or custom design for larger vessel

- integrated 600 dpi Thermal transfer printer

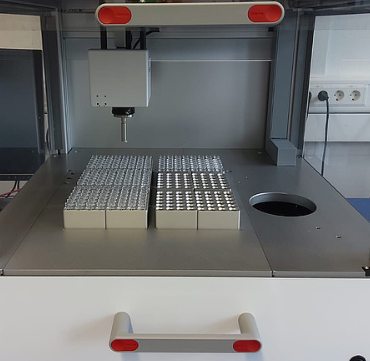

SampliTAG - Tube Labeler

The SampliTAG is an excellent alternative to expensive, fully automated solutions for flexible, small-scale production.

- 10 positions worktable for SBS format racks or customized format

- Control completely integrated into the device

- Operation via external PC

- Vacuum gripper, automatic tube and height detection, tubes from 20-130 mm possible

- Integrated thermal transfer printer, 600 dpi

SampliKiT

To create clinical study kits, valuable working time is often lost because many processes are still manual. Tubes are manually labeled, sorted and filled into bags. Data is assigned manually to the studies. Tubes are manually reworked both at the sample sites and later at the sample entrance.

- Tube Handler Base for tubes from 10 – 60mm

- 15-position tray table for SBS format racks (3×5))

- Bagging Machine

- Labeler for blood collection tubes – not limited to manufacturer

- thermo transfer printer for cryotubes

HEN Mini

Innovation in the preparation and management of the blood collection phase

- Modular storage units

- Integrated barcode reader for check in and check out

- High speed: over 300 tubes/hour

- Robotic tube collection system for labelling

- ntegrated barcode reader and label printer

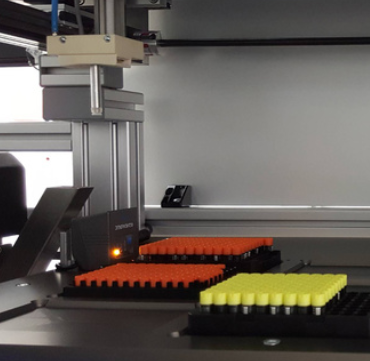

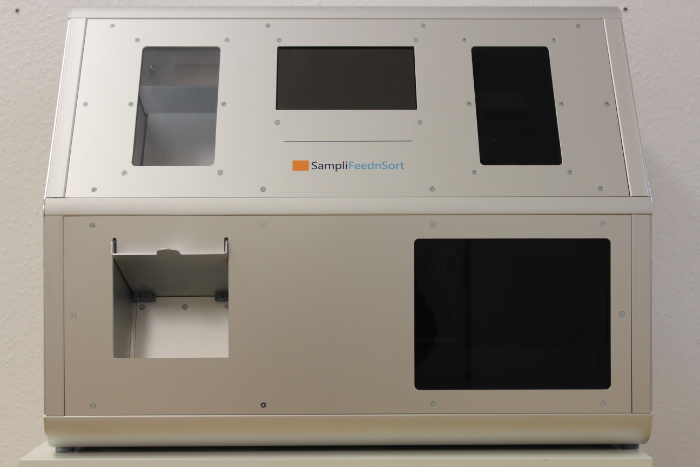

SampliFeednSort

- The newly developed step conveyor allows high transport speed with consistently precise alignment of the tubes. Two connected conveyor belts ensure further transport. The feeder holds approx. 800 – 1000 tubes, depending on the size of the tubes.

- The new freedom when sorting: Click on individual layouts/patterns or save up to 10 recurring processes as fixed programs. If you want to deviate from the pattern, this can easily be changed using the touchscreen. It is only saved if you press save.

- An integrated camera system ensures optimal process monitoring. Intelligent image processing recognizes the desired tube. Defective tubes are sorted out.

The device is trained for all the tubes present. Errors that have already occurred are taken into account with the error correction program.

2D bottom or side barcode scanner

- A 2 D bottom barcode scanner can be used to retrieve data as well as to verify the barcode.

- The barcode data can be used either as import or export file.

- Can be used with all standard 2 D bottom barcodes from Matrix, Brooks, Micronic, Greiner, LVL and others. Barcoded labels are easy to verify with the side barcode scanner.

- A process control that is very easy to implement.

- Device: SampliTag HP

Rack and deck solutions

With the Sci-Print VX series you are able to label many different tube types and also special solutions such as syringes. You can already choose from more than 50 custom-made products.

- Rack SBS format cryotubes

- Complete cover for conical tubes/li>

- Complete cover for cryotubes/li>

- Complete deck occupancy for vacutainers

Bag packing machine

- V15 bags per minute – all related to the tube processing

- Bag size: B 50mm – 250mm / L 100mm – 430mm

- Filling weight: Max. 1 Kg

- Interfaces: USB, seriell, Ethernet

Liquid Handling Modules

- Optimize your aliquoting of day-to-day quality control samples with our liquid handling modules. Easily place source tubes or vials on the SampliTAG HP. Our modules can handle pipette tips with a maximum tube size of 250 ml, while larger containers can be processed with a special liquid handling module.

- The selection of the appropriate liquid handling module depends on the desired aliquoting volume and the source vessel. We can offer pipette tips, positive displacement or a pump module.

- Let us know your requirements and we will recommend the right solution for you.

- Device: SampliTag HP

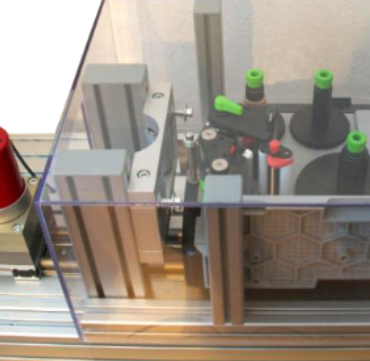

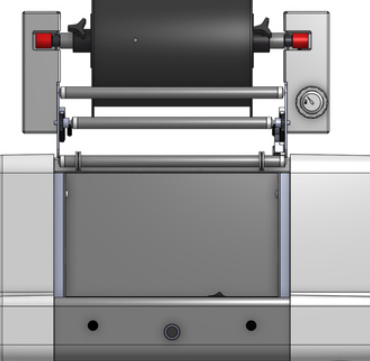

Capper / Decapper

-

- Our capper/recapper is individually adapted to the tubes or vessels you use.

- Before each aliquoting process, you have the option of first labeling the tube and then filling it. In this case, the cap of the tube is removed before filling, the tube is transported to the liquid handling station and closed again after filling. Labelling can be added before or after this process.

- Alternatively, the capper can also be used exclusively for removing lids.

- Device: SampliTag HP

Weighing system

-

- The weight control of liquids or solids in vessels is widely used in analytics.

- Our weighing system offers the option of weighing vessels either before labeling as empty vessels or weighing the filled tube after the process. The vibration-free mounting of the balance ensures precise measurements.

- Simply place a tube in the opening provided and have it weighed. The data is seamlessly transferred to a CSV export file.

- Device: SampliTag HP