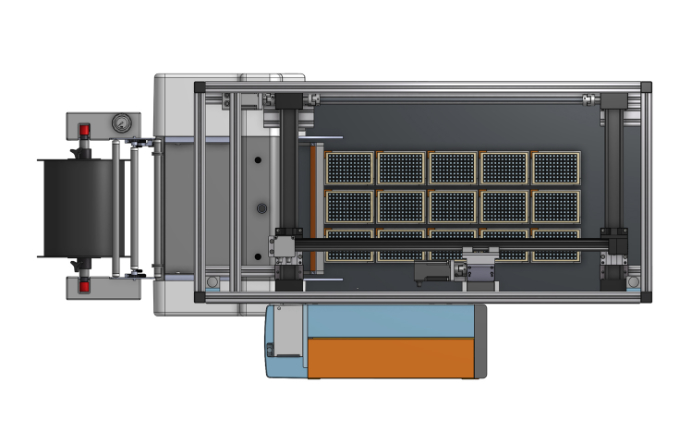

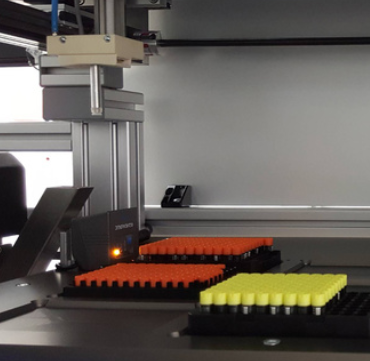

Base unit Tube Handler

for tubes from 10 – 60mm

- Tray table modifiable according to customer requirements

- Control unit completely integrated

- Vacuum gripper

| Category | Process solution |

| Operation | Touchpanel |

| Compressed air connection | 6 bar |

| Connections |

3x USB Network: RJ45 |

| Dimensions |

Width: 1250mm High: 1090mm Depth: 600mm only base unit |

| Weight | 75 kg |

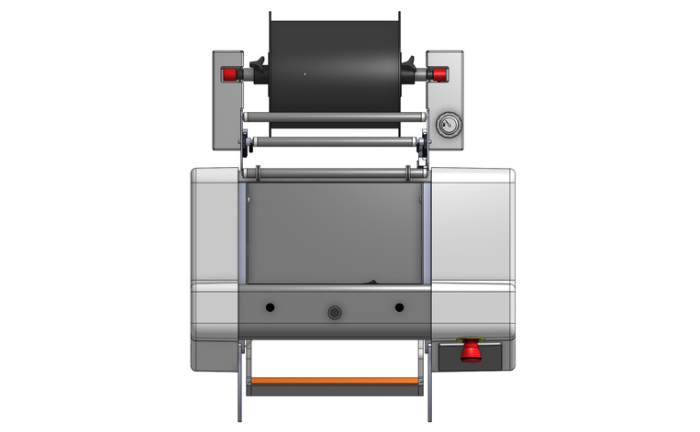

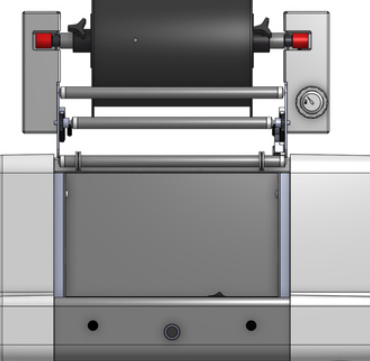

Bag

Maschine

| Packing speed | 15 bags per minute |

| Bag size | Width: 50mm – 250mmHöhe: 100mm – 430mm |

| Filling weight | 1 kg |

| Interfaces |

USB serial Ethernet |

Labeler for blood collection tubes

not limited to manufacturer

- Mobile labeling system for up to 140 blood collection tubes

- integrated customer-specific loading compartments

- high speed over 300 tubes per hour

- for all types of blood collection tubes also Sarstedt

- integrated barcode scanner and label printer

- easily accessible side door for changing label roles

- Simple loading of the loading compartments with blood collection tubes

- Thermal direct printer, freely selectable label design

- Integrated additional label printer for 1, 2, 3 or more labels/li>

Process solution

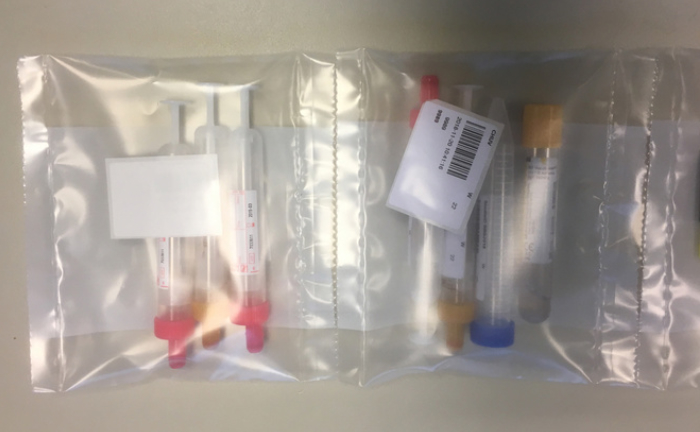

SampliKiT – production of clinical trial kits

SampliKiT for the production of clinical study kits

To create clinical study kits, valuable working time is often lost because many processes are still manual. Tubes are manually labeled, sorted and filled into bags. Data is assigned manually to the studies. Tubes are manually reworked both at the sample sites and later at the sample entrance.

With the SampliKit you gain valuable working time and have the process under control. Not only the process itself, also the tracking process is completely in your hands.

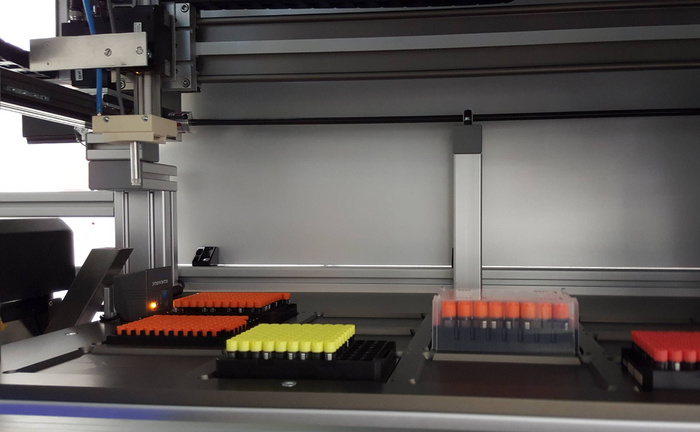

So far, you have left this task to service providers and CROs and want to control the process of your study kits yourself, then the SampliKit offers full flexibility in the use of different tube sizes and formats. The intelligent gripper can process different tubes on a single platform. An integrated and mobile barcode scanner attached to the gripper arm allows scanning of 1D or 2D barcodes during the picking process, thus increasing the working speed. No matter if the barcode is on the bottom or on the side of the tube, everything is legible.

Tubes with a height of 10mm – 60mm can be processed on the same platform. There is space for 10 x SBS format racks. The device is adaptable to all formats that can be used automatically. Contact us if you want to understand more!

On request, the device can be supplemented with a printer, a dispenser or a balance. The device has enough interfaces for importing or exporting data from LIMS / LIS or KIS.

- Tube Handler Base for tubes from 10 – 60mm

- Bagging Machine

- Labeler for blood collection tubes – not limited to manufacturer

- Tube Handling, packaging ready to use clinical trial kits

Tube Handler und Sorter KIT – Patienten-Kits – Pics

Video SampliKiT

Options can be retrofitted at any time

- Weighing cell – Weighing of sample content / input and output control possible

- Printer – Labeling of sample containers

- Turning mechanism for capping and recapping – with stepless gripper only Dispensing pump – filling of tubes with buffer or any other solution

- Reeding system for bulk material

- RFID labeling on request

- Examples of packaged clinical trial kits

Components

Bag maschine

- Packing speed: 15 bags per minute

- Bag size: B 50mm – 250mm / L 100mm – 430mm

- Filling weight: max. 1 Kg

- Interfaces: USB, seriell, Ethernet

Labeling system for blood collection tubes from all manufacturers

- Automatic labeling System/li>

- Easy tube supply

- Expandable module

- Label attachment position detection system

- Exact placement of the label can be defined be the user.